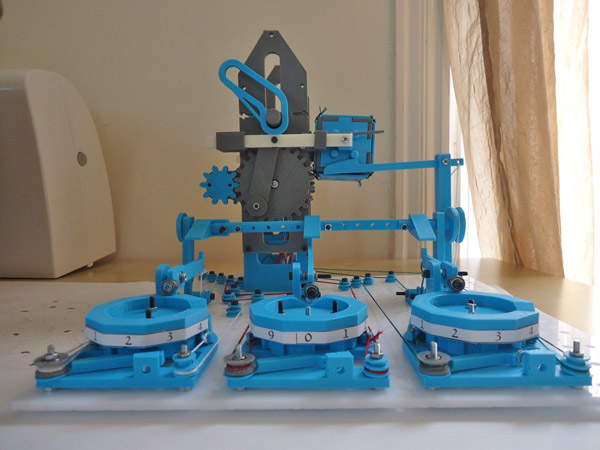

As demonstrated by the Greeks in their Antikythera mechanism, computers are not all about 1s and 0s. Chris Fenton’s 3D printed mechanical computer, for example, requires a bit of cranking in order to perform tabulations.

Chris Fenton is a designer and electrical engineer that spends most of his work day around very fast computers. As you can see on his website, he’s quite a fan of 3D printed contraptions, and given the mechanical nature of these gadgets, it’s no wonder that after a day’s work, Fenton prefers to spend his spare time on things that move slower.

The Turbo Entabulator, as Fenton called his implementation of his mechanical FIBIAC machine, is inspired from an 1895 copy of The Mechanism of Weaving. It should be noted that while his FIBIAC machine was an electromechanical computer that uses punch card to calculate the Fibonacci sequence, the Turbo Entabulator is entirely mechanical and for the most part, 3D printed.

The 3D printed computer includes nuts, bolts, springs, rubber bands and a few small bearings, along with punch cards, which are also 3D printed. It has a steampunk air to it, if only the color palette matched the theme. Nowadays, there are plenty of 3D printers that print in color, but considering how many of Fenton’s projects are brought to life using this method, he probably doesn’t want to invest more in an expensive 3D printer, since the functionality would be the same, and that’s what really matters for him.

“Run the machine under water if you want, it won’t care. It’s all ratchets, gears, and pulleys. The machine is entirely driven by a central crank-shaft with a handle attached to it. Want to overclock this monster? Crank faster. There is something about entirely mechanical systems I find appealing. The inner workings aren’t hidden in a nanometer-sized sliver of silicon, operating on pico-second timelines,” explained Fenton.

Assuming that Fenton got this right the first time would be a mistake. He pointed out that building the Turbo Entabulator was very much a trial-and-error process, and that he went through around 20 iterations of the machine before being satisfied with how it looked and worked.

I also liked the fact that Fenton named his 3D printed computer after the turbo-encabulator, a fictional machine that became an in-joke for engineers. The designer was also kind enough to offer the blueprints necessary for 3D printing the parts at home, should anyone want to reconstruct his project.

Be social! Follow Walyou on Facebook and Twitter, and read more related stories about the 3D4C 3D printer that combines four filaments for a wide range of colors, and Disney Research’s 3D printed hair.