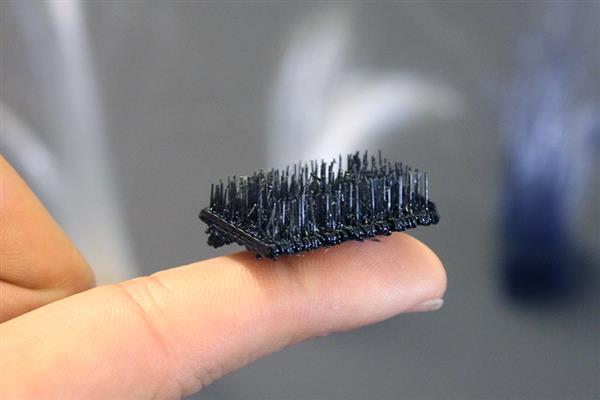

A technique developed by researchers at Carnegie Mellon University has just turned 3D printed silky hair into a reality.

Furbrication, as this technique is called, can be used for making touchably soft fibers and bristles in a manner that resembles pulling a hot glue gun away from the object it has touched. Gierad Laput, Xiang ‘Anthony’ Chen, and Professor Chris Harrison, the three researchers who came up with the idea, realized that typical 3D printing methods (which typically imply extruding melted plastic and placing it layer upon layer) won’t be good enough for 3D printing hair and bristles, and proceeded to inventing a new technique.

First displayed publicly at the Engadget Live event in Brooklyn, New York, the 3D printed hair doesn’t require any special machines for producing it. As Gierad Laput, one of the PhD students involved in the development of this technique, “You just squirt a little bit of material and pull away. It’s a very simple idea, really.”

As emphasized before, the technique can be used for making both soft strands of hair, and stiffer bristles. This is achieved by modifying the root positions. Randomized root positions lead to silky fibers, while uniform root positions generate toothbrush-like bristles.

Back in August 2014, Disney Research announced that they had found a way of 3D printing human hair accurately. Whereas Disney Research’s approach lead to accurate impressions of a person’s hairstyle, furbrication is able to produce individual strands of hair.

“We introduce a technique for furbricating 3D printed hair, fibers and bristles, by exploiting the stringing phenomena inherent in fused deposition modeling 3D printers,” added the three researchers. “We show several examples of output, demonstrating the feasibility of our approach on a low cost printer. Overall, this technique extends the capabilities of 3D printing in a new and interesting way, without requiring any new hardware.”

Horse tails for new toys can be 3D printed equally easy using this technique. I’m definitely not thinking of My Little Pony adopting this 3D printing method.

Beards of wizards and shaolin monks can be adjusted to the desired length once 3D printing is done.

Assuming that this process is cheaper, furbrication could allow people to 3D print their toothbrushes, with the precise bristle hardness and density that they need.

All in all, given that these results were achieved with $300 FDM 3D printers and common PLA 3D printing filaments, the entire technique is rather impressive.

The researchers are now looking into 3D printing individual strands of ABS or even materials with magnetic properties.

Now that it’s finally possible to 3D print toupées, will we get to see more trolls looking like Donald Trump? I’m not saying that his counter-candidates should pick up this idea, but I don’t think that people would mind if they did. Jokes aside, the paper titled “3D Printed Hair: Fused Deposition Modeling of Soft Strands, Fibers and Bristles” explaining how this technique works is available in PDF format here.

Be social! Follow Walyou on Facebook and Twitter, and read more related stories about Disney Research’s method of 3D printing hair accurately, or the world’s first 3D printed vertebra implant.

[via 3Ders]