Komatsu Forest harvesters bring a whole new meaning to yelling timber. The company specializes in developing harvesters and logging software. These machines are so complex that it can take up to two years to get use to all the features they have. These harvesters have a lot of power being pumped through them, so it can be difficult to work because the cab will vibrate, and weather conditions are typically not the best.

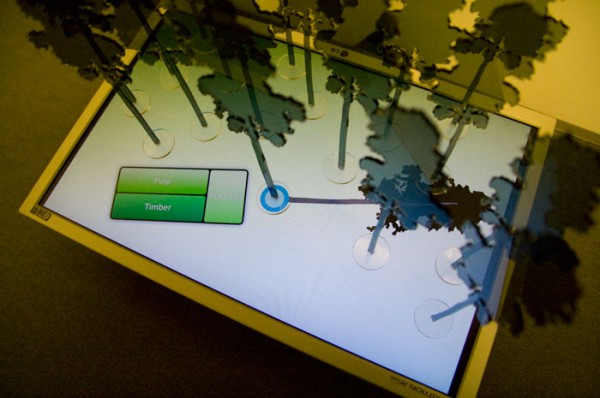

So, Komatsu Forest got together with Umeå Institue of Design in order to improve the way operators use the harvesters. The software is designed to make as many things automated as possible. One part of the design is to be able to scan the forest and determine what tree the operator wants cut down. The automation system will identify where to optimally position the machine and where the tree will fall according to where it is positioned. To do this, the system will locate other trees and objects close to the tree and angle itself in a direction that will cause the tree to fall in the best location.

After cutting down the tree, the operator will chose where he wants the different qualities of log to be placed. Then the harvester will cut the logs into different sections and be able to determine the quality of each log, whether it’s straight, bent, etc. While it does this, it will also de-limb the tree. The process is actually very complicated with many graphs for how things, and when things, happen as well as what will happen when something goes wrong.

Although the concept is a very complicated system it will allow operators to be trained much quicker on how to optimally use the harvester and not have to be waiting two years to fluently be yelling timber.

For more interesting systems see the Jolicloud operating system and the stream adaptive computer system

Via: Zenona