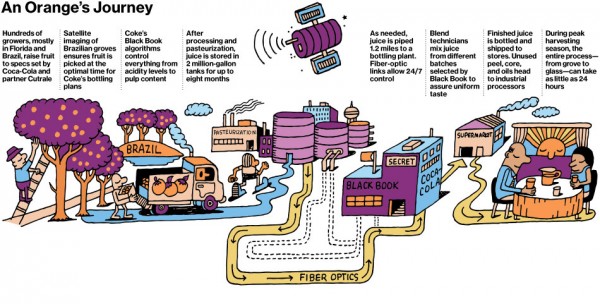

Taking mother nature and standardizing it. That is what it takes to bring orange juice (Coca-Cola’s OJ in this example) to your table: much more than just pick, squeeze, and pour.

Juice production is full of variables, from weather to regional consumer preference, and Coke is trying to manage each from grove to glass. Auburndale, an hour south of Disney World: Here, Coke has perfected a top-secret methodology it calls Black Book to make sure consumers have consistent orange juice 12 months a year, even though the peak growing season lasts about three months.

Black Book isn’t a secret formula; it’s an algorithm. An algorithm that requires analyzing up to 1 quintillion decision variables to consistently deliver the optimal blend, despite the whims of Mother Nature.

The Black Book model has detailed data about more than 600 flavors that make up an orange, and consumer preferences. The data is matched to a profile according to acidity, sweetness, and other attributes. The algorithm then tells Coke how to blend batches to replicate a certain taste and consistency, right down to pulp content.

Working together with Curtale from Brazil, Coke’s partner in the Juice wars around the world and in the United States, the companies constructed a 1.2-mile underground pipeline from Cutrale’s Orlando-area processing operation to Coke’s packaging plant to transport juice that previously required 70 tanker-truck trips daily.

No part of the orange during the process of producing OJ is wasted. Essential oils are bottled and sold for everything from flavoring to household cleaners. Peel is pressed into pellets for cattle feed. The raw juice is then flash-pasteurized and piped to storage tanks as large as 2 million gallons each for up to eight months. Batches of juice from various crops and seasons are segregated based on features such as orange type, sweetness, and acidity. In-season juice is typically mixed with off-season juice.

All that tweaking doesn’t suit everyone’s taste, but it doesn’t really matter when sells are going extremely well, despite selling at a price that’s usually about 25% higher than the competition’s. Some have called for stricter labeling so they know the juice has been engineered from various batches of oranges. There’s still one part of the process that hasn’t changed with time: picking. About 95 percent of the oranges Coke uses for juices are still plucked from trees by hand.

Hat Tip